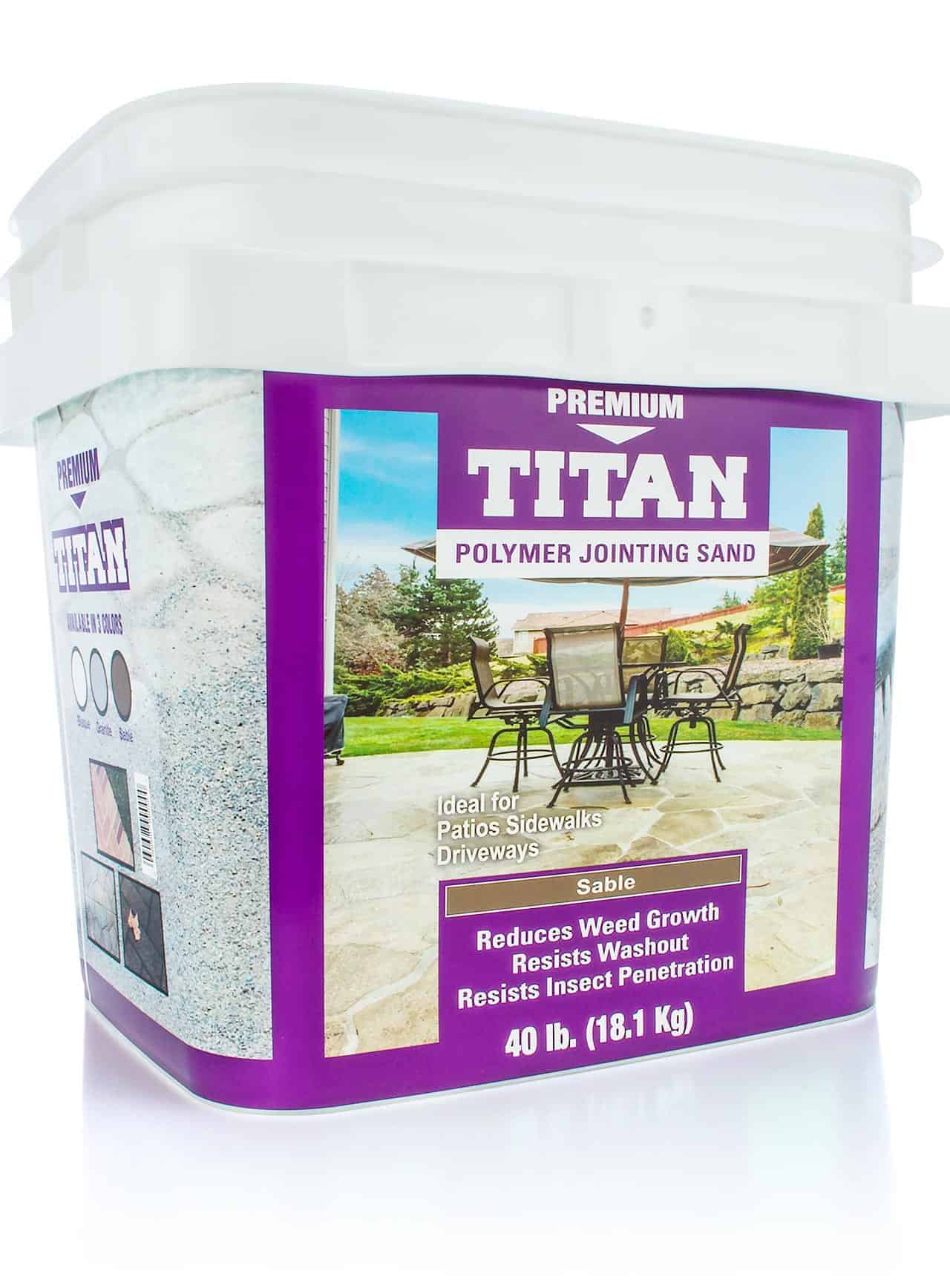

IML (In-Mould Labeling) is the integration of a label with the packaging during the moulding process. The label is placed into the package mould, then the polymer combines with the label and takes the shape of the mould.

Thus, both production of packaging and labeling are performed at the same time. IML process can be applied with blow moulding, injection moulding and thermoforming technologies.

IML has become more widely used by sectors such as food, industrial pails, chemistry, health etc.

Advantages of IML:

- Environmentally friendly

- Durable in harsh environments

- Provides wide ranges of effects such as matte, high-gloss, orange peel, partial lacquer, No-Label-Look etc.

- Offers high-quality graphics

- No post labeling step is necessary

- Faster production line speeds are possible

- Can be applied to corners and complex shaped containers

Contact us to learn more!